Men's Winter Shoes Casual Style for Comfort and Warmth

There are also more diverse designs in appearance.

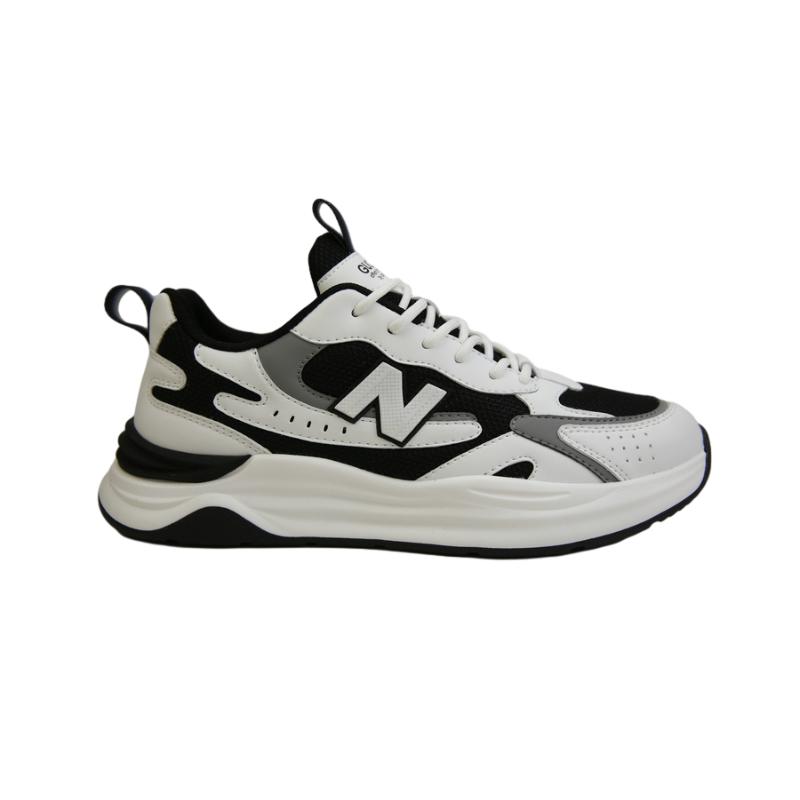

womens sports shoes sale. It’s about recognizing the importance of women's participation in sports and their specific requirements. By spotlighting women's sports shoes, retailers acknowledge the diverse range of activities women engage in and the gear needed to excel in them. This focus sends a message of inclusivity and encouragement, inviting women to explore new horizons and push their limits.

womens sports shoes sale. It’s about recognizing the importance of women's participation in sports and their specific requirements. By spotlighting women's sports shoes, retailers acknowledge the diverse range of activities women engage in and the gear needed to excel in them. This focus sends a message of inclusivity and encouragement, inviting women to explore new horizons and push their limits.

When it comes to working in hazardous environments, nothing is more essential than a sturdy pair of safety footwear. Among various options available, men's safety Wellington boots have emerged as a popular choice due to their unique blend of protection, waterproof capabilities, and comfort. Suitable for a myriad of industries, including agriculture, construction, and outdoor maintenance, these boots are designed to safeguard one’s feet while ensuring ease of movement.

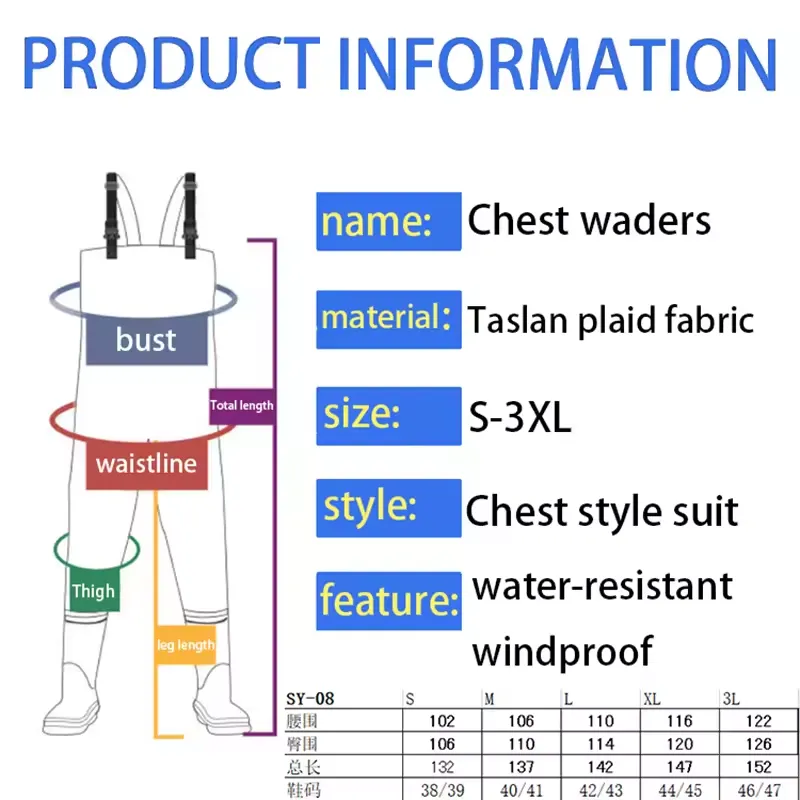

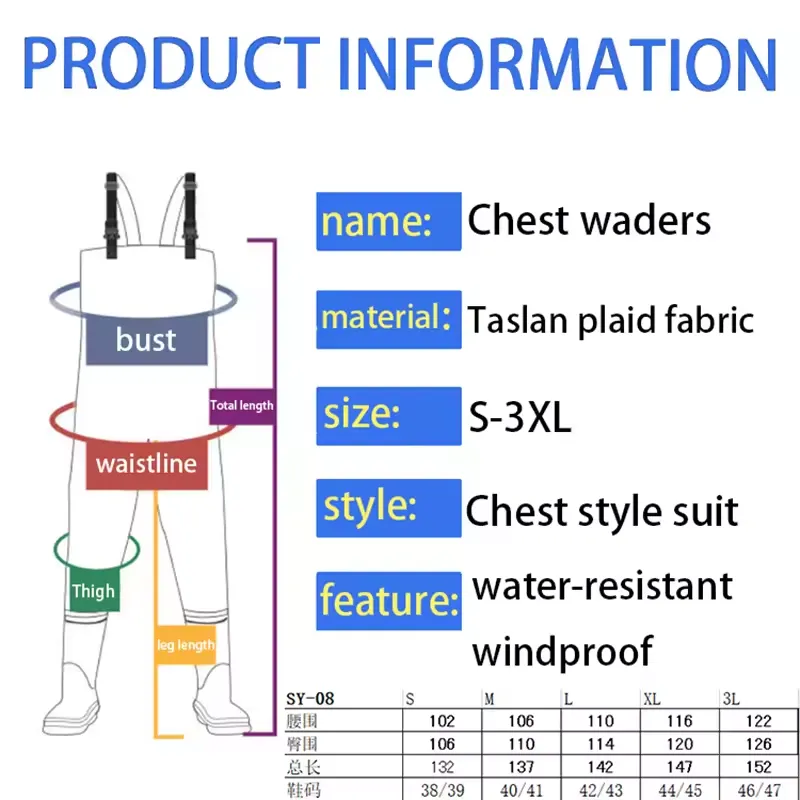

When choosing fishing boots, you may want to consider more comfort and lightness. Some manufacturers specifically design breathable, lightweight fishing boots to ensure comfort during extended fishing sessions. Brands like Cabela's, Simms, and Hodgman offer a variety of styles and affordable options to suit different fishing needs.

Choosing the Right Pair

When it comes to footwear designed for extreme weather conditions and adventurous outdoor activities, rubber pack boots stand out as a popular choice. These boots, also known for their durability and waterproof qualities, are particularly favored during the fall and winter months, when the weather can be unpredictable and challenging. Let’s explore the features, benefits, and various uses of rubber pack boots, making it clear why they deserve a place in your winter wardrobe.

Camouflage and Design

Moreover, rubber is known for its robustness and grip, which means these boots can handle both urban sidewalks and more rugged terrains with equal aplomb Moreover, rubber is known for its robustness and grip, which means these boots can handle both urban sidewalks and more rugged terrains with equal aplomb

Moreover, rubber is known for its robustness and grip, which means these boots can handle both urban sidewalks and more rugged terrains with equal aplomb Moreover, rubber is known for its robustness and grip, which means these boots can handle both urban sidewalks and more rugged terrains with equal aplomb men's slip on rubber ankle boots.

men's slip on rubber ankle boots.Rubber type

In conclusion, the 38x52x7 oil seal is an essential component in many types of machinery, providing reliable protection against oil leakage and helping to extend the life of mechanical components. By selecting the right seal for the application and ensuring proper installation and maintenance, you can help to ensure the efficient and reliable operation of your machinery.

Nitrile rubber (NBR)

Crankshaft front seal